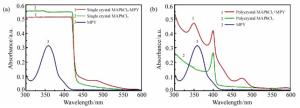

Here the low-temperature oxidation regime of α-iron was studied at 450 ☌, where thin, more protective two-phase oxide scales grow on iron substrates. To this end, the oxidation behavior of a pure iron single crystal with (110) surface orientation is compared to the one of a polycrystalline Armco iron. The present work is therefore devoted to the influence of substrate orientation and preferential orientation of oxide growth on the internal stress state of oxide scales.

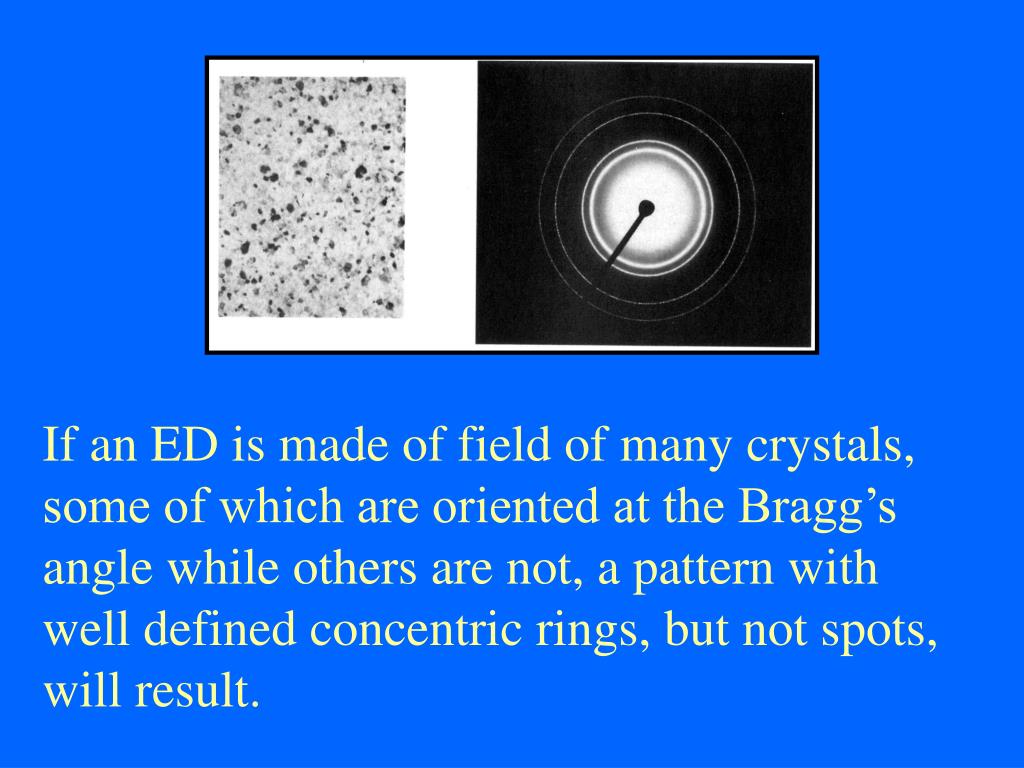

Owing to the diversity of mechanisms for stress generation in oxide scales, the time dependence of growth stresses has also been modeled only for cases where an individual oxide phase grows on the metallic substrate without considering possible orientation relationships between substrate and oxide. Under these conditions, the role of substrate orientation in the crystallographic texture of the oxides and therefore in the internal stresses of the oxide scale can not be evidenced. However, internal stresses have been mostly studied in oxide scales forming on polycrystalline substrates. The distinct oxidation behavior of single crystals might be associated therefore with particular internal stress states resulting from preferential orientations of oxide growth. In addition to growth strains, the crystallographic orientation of the substrate can also influence the oxidation kinetics. Among the diverse models proposed over the past years, volumetric changes between the oxide formed and the metal consumed according to Pilling and Bedworth, the growth of new oxide in oxide grain boundaries and epitaxial growth appear to be the most relevant mechanisms. The sources of growth stresses within oxide scales are manifold. These mismatches give rise to internal stresses capable of deteriorating the shielding efficiency of those surface layers against the destructive reaction between the metal and the corrosive agents. Differences in polarization-versus-electric-field and strain-versus-electric-field behavior between the hot-pressed and annealed materials have been discussed in terms of differences in domain mobility.The formation of oxide scales on metallic substrates exposed to corrosive environments and high temperatures is invariably accompanied by growth incompatibilities. The transition on annealing has been explained in terms of chemical homogenization to a near-morphotropic phase-boundary composition that is intrinsically weak normal-ferroelectric. The as-hot-pressed properties have been explained as being the integrated response of many discrete ferroelectric responses as dictated for each of these regions by the local chemistry. The as-hot-pressed microstructure was chemically heterogeneous, characterized by submicrometer-sized regions of varying magnesium, niobium, and titanium content that likely originated from chemical heterogeneities that were present in the as-prepared PMN-PT powder. Annealing resulted in a transition to weak normal-ferroelectric behavior, a shift in the dielectric maximum temperature from 190☌ to 169☌, and a dramatic increase of to a maximum value of 41 720 for the longer anneal. The as-hot-pressed material exhibited relaxor–ferroelectric-like behavior, with a relatively low dielectric constant maximum measured at 1 kHz of 8160. Dielectric and piezoelectric properties of the as-hot-pressed and annealed samples were measured and correlated with microstructure. Fully dense compacts were formed by hot-pressing the powder at 950☌, and then the compacts were annealed at 1150☌ for 5 and 10 h, respectively. PbO3 (PMN–35PT) powder was prepared using the columbite precursor method.

0 kommentar(er)

0 kommentar(er)